Classification And Characteristics Of Common Luggage Fabrics

Posted by Admin

What are the classification and characteristics of common luggage fabrics?

PVC/PU leather

In China, people are accustomed to using PVC resin as raw material to produce artificial leather called PVC artificial leather (referred to as artificial leather); Artificial leather produced with PU resin as raw material is called PU artificial leather (referred to as PU leather): Artificial leather produced with PU resin and non-woven fabric as raw material is called PU synthetic leather (referred to as synthetic leather).

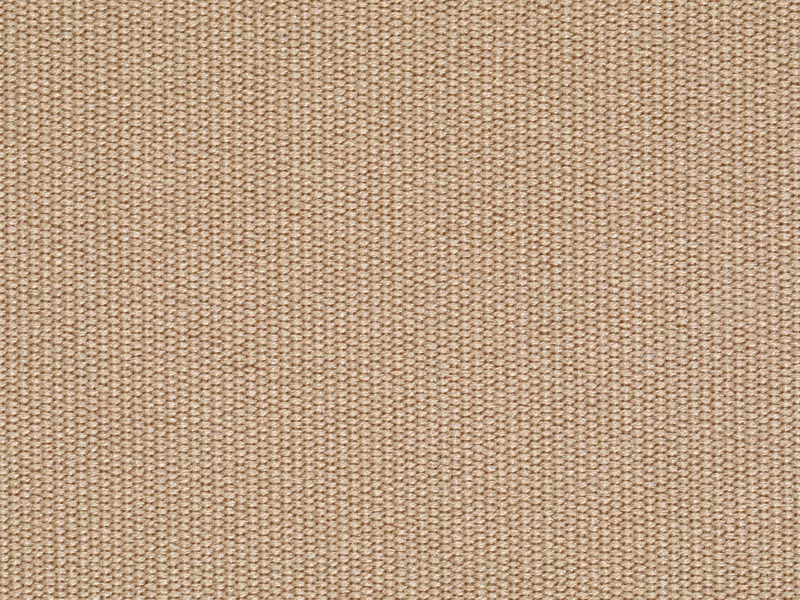

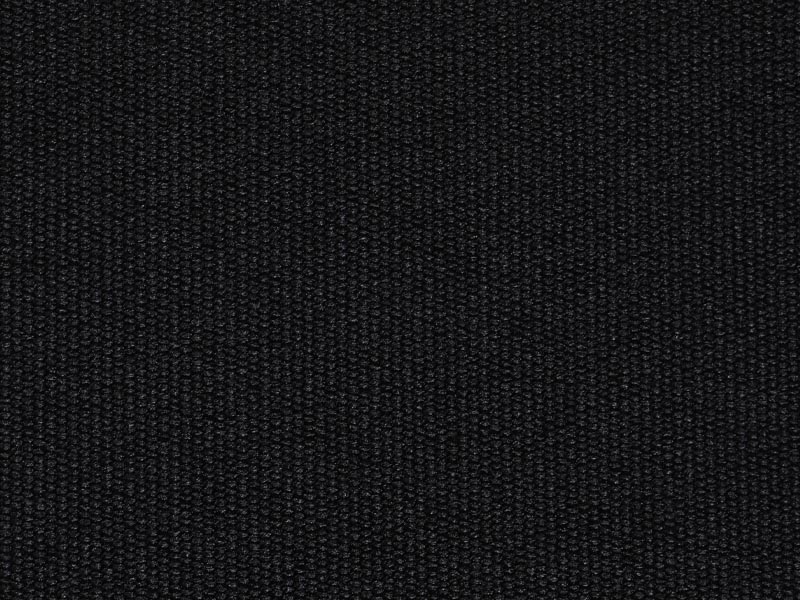

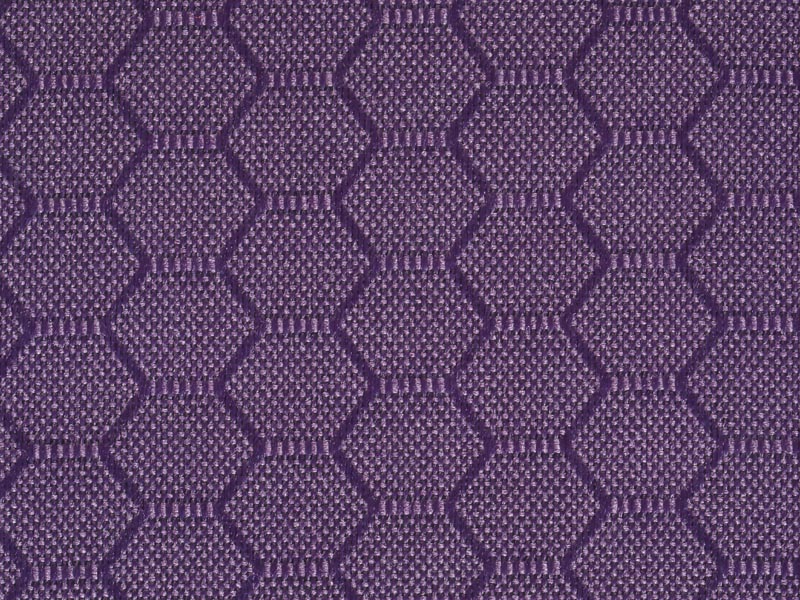

Nylon/Oxford cloth

Oxford cloth is a new type of fabric with diverse functions and vast uses. Currently, there are mainly varieties on the market, such as woven fabric, full stretch fabric, nylon fabric, and jacquard fabric.

Non woven fabric

Non-woven fabrics can be divided into:

1. Spunlaced nonwoven fabric: It sprays high-pressure micro water onto one or more layers of fiber mesh, causing the fibers to intertwine with each other, thereby strengthening the fiber mesh and providing a certain strength.

2. Heat-bonded nonwoven fabric: refers to the addition of fibrous or powdery hot melt adhesive reinforcement materials to the fiber web, which is then heated, melted, and cooled to form a fabric.

3. Pulp air flow net forming nonwoven fabric: Also known as dustless paper, the dry paper makes nonwoven fabric. It uses airflow web developing technology to loosen the wood pulp fiberboard into a single fiber state, then uses the air flow method to agglomerate the fibers on the web curtain, and the fiber web is then reinforced into a cloth.

4. Wet process non-woven fabric: It is to loosen the fiber raw materials placed in the water medium into a single fiber while mixing different fiber raw materials to make a fiber suspension slurry. The suspension slurry is transported to a web-forming mechanism, and the fibers are formed into a web in the wet state and then reinforced into a fabric.

5. Spunbonded nonwoven fabric: After the polymer has been extruded and stretched to form continuous filaments, the filaments are laid into a web, which is then subjected to self-adhesive, thermal adhesive, chemical adhesive, or mechanical reinforcement methods to turn the web into a nonwoven fabric.

6. Melt-blown nonwoven fabric: Its technological process: polymer feeding - melt extrusion - fiber formation - fiber cooling - web formation - reinforcement into the fabric.

7. Needled nonwoven fabric: It is a type of dry process nonwoven fabric that utilizes the piercing action of a needle to reinforce a fluffy fiber mesh into a cloth.

8. Stitching nonwoven fabric: It is a type of dry process nonwoven fabric. Stitching is using warp-knitted coil structures to reinforce fiber webs, yarn layers, nonwoven materials (such as plastic sheets, plastic thin metal foils, etc.), or their combinations to make nonwoven fabrics.

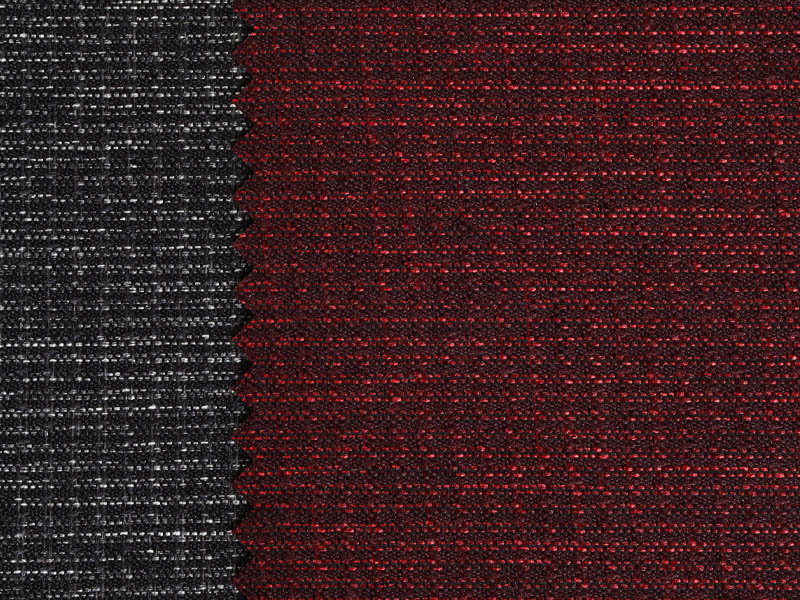

Denim/Canvas

Denim is made of pure cotton indigo dyed warp yarn and natural weft yarn, interwoven with three upper and lower right twill weave patterns. It can generally be divided into three categories: light, medium, and heavy. The width of the cloth is mostly between 114 and 152 centimeters.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt