Common Types And Uses Of Composite Fabric

Posted by Admin

PU/PE/PVC composite fabric is a revolutionary material that combines the strengths of polyurethane (PU), polyethylene (PE), and polyvinyl chloride (PVC) to create a fabric with exceptional durability, versatility, and performance. This composite fabric has gained popularity in various industries for its ability to withstand challenging conditions and provide reliable protection.

PU composite fabric, also known as polyurethane composite fabric, is renowned for its outstanding waterproof and windproof properties. PU is a versatile polymer that can be applied as a coating to the fabric, creating a barrier that prevents water penetration. This feature is particularly important in outdoor gear, such as raincoats, tents, and backpacks, where users rely on reliable waterproofing to stay dry in adverse weather conditions. The PU coating also enhances the fabric's resistance to wind, providing an additional layer of protection against the elements.

PE composite fabric, or polyethylene composite fabric, offers excellent strength and durability. PE is a thermoplastic polymer known for its toughness and resistance to impact. When used in a composite fabric, it adds strength and stability to the material, making it suitable for heavy-duty applications. PE composite fabric is often used in industrial settings, such as protective clothing, construction tarps, and cargo covers, where durability and reliability are paramount.

PVC composite fabric, or polyvinyl chloride composite fabric, is highly regarded for its exceptional chemical resistance and flame retardancy. PVC is a thermoplastic polymer that exhibits excellent resistance to chemicals, oils, and solvents. When incorporated into a composite fabric, it provides a protective layer that shields against corrosive substances, making it ideal for applications in industries such as manufacturing, agriculture, and transportation. Additionally, PVC composite fabric is inherently flame retardant, offering an added level of safety in environments where fire hazards are a concern.

The combination of PU, PE, and PVC in a composite fabric creates a material that excels in both performance and versatility. This fabric can be engineered to meet specific requirements, such as desired levels of flexibility, weight, and breathability. Manufacturers can tailor the composite fabric to suit various applications, ranging from lightweight rainwear to heavy-duty industrial covers.

PU/PE/PVC composite fabric is also known for its ease of maintenance and long-lasting performance. It is typically resistant to stains, mildew, and UV degradation, ensuring that the fabric retains its appearance and functionality even after prolonged use. Additionally, the fabric can be easily cleaned using mild detergents or wiped with a damp cloth, making it a practical choice for applications where cleanliness is essential.

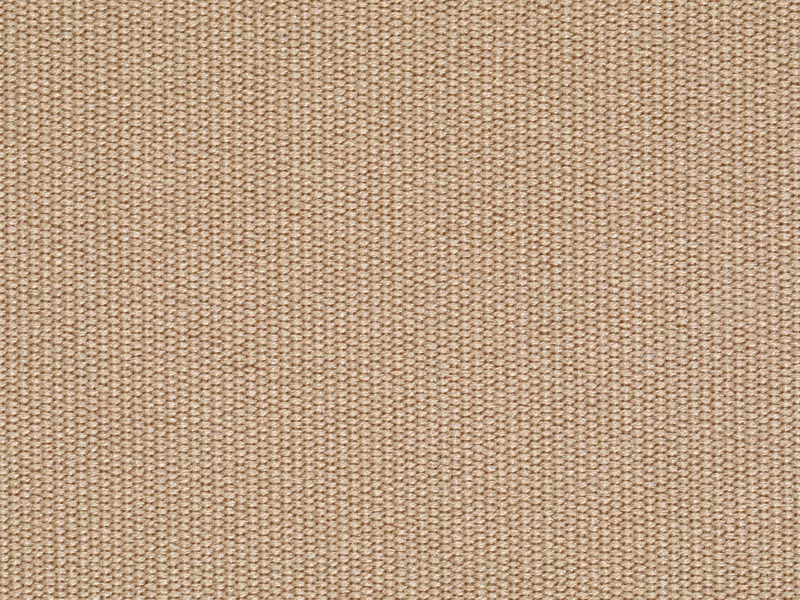

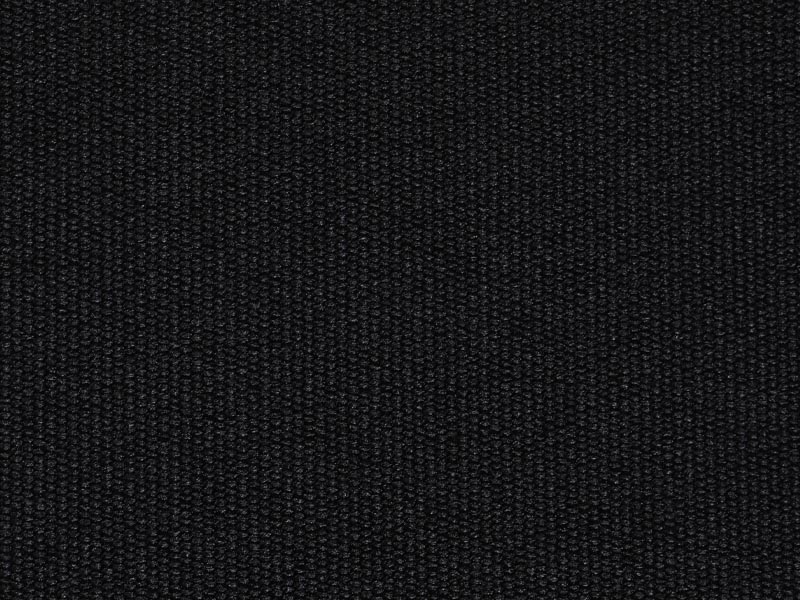

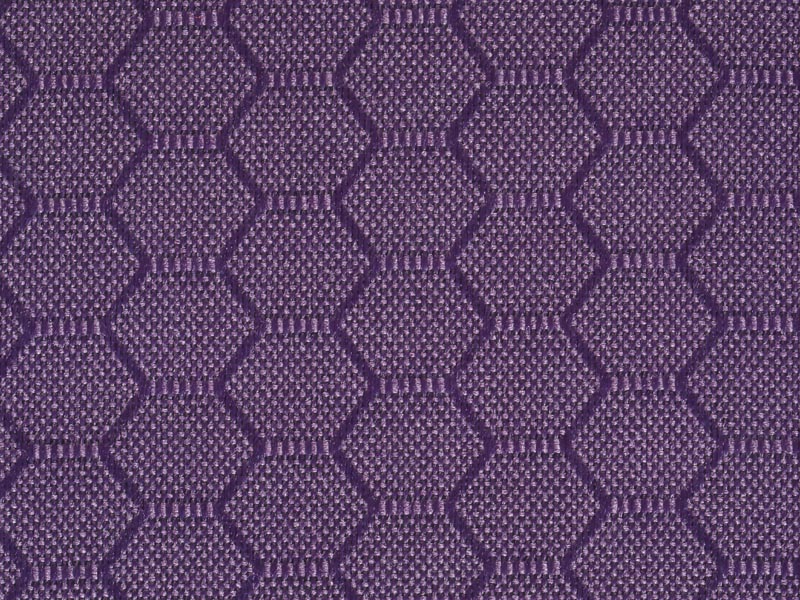

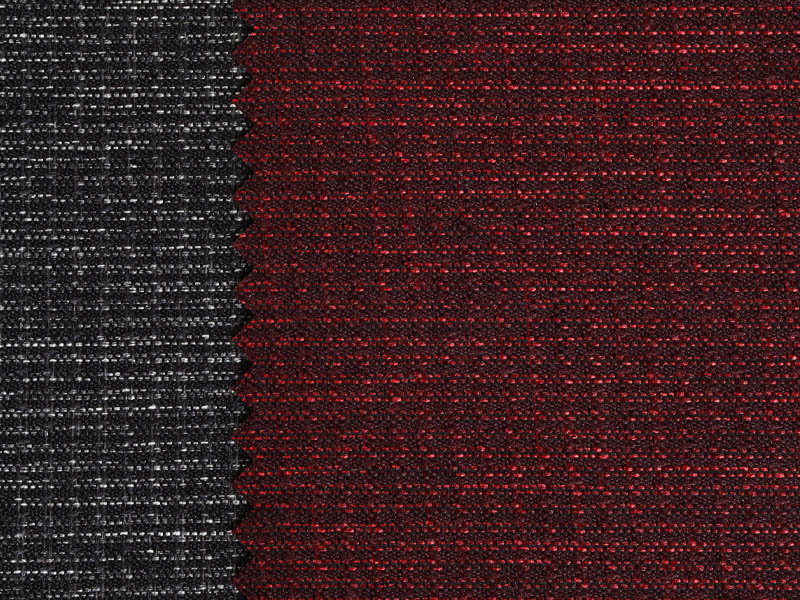

Furthermore, PU/PE/PVC composite fabric offers a wide range of design possibilities. It can be manufactured in various colors, patterns, and textures to cater to different aesthetic preferences. This flexibility allows manufacturers to create products that not only provide superior performance but also reflect the style and identity of the users.

In conclusion, PU/PE/PVC composite fabric is durable and versatile material that combines the strengths of polyurethane, polyethylene, and polyvinyl chloride. Its waterproof, windproof, chemical-resistant, and flame-retardant properties make it ideal for a wide range of applications in industries such as outdoor gear, industrial manufacturing, and protective clothing. With its exceptional performance, ease of maintenance, and design versatility, PU/PE/PVC composite fabric continues to be a preferred choice for manufacturers and consumers seeking reliable and high-performing materials.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt