Sustainable Innovations in Tent Fabric

Posted by Admin

Wholesale nylon tent Fabric Material Factory

In the realm of outdoor equipment, Tent Fabric is a critical component that determines the performance, durability, and environmental footprint of tents. As the world becomes increasingly aware of the need for sustainable practices, manufacturers of Tent Fabric are at the forefront of innovation, striving to create materials that are not only functional but also kind to the planet. This article delves into how these manufacturers are adopting eco-friendly materials and production processes and discusses the development of recyclable and biodegradable Tent Fabric options.

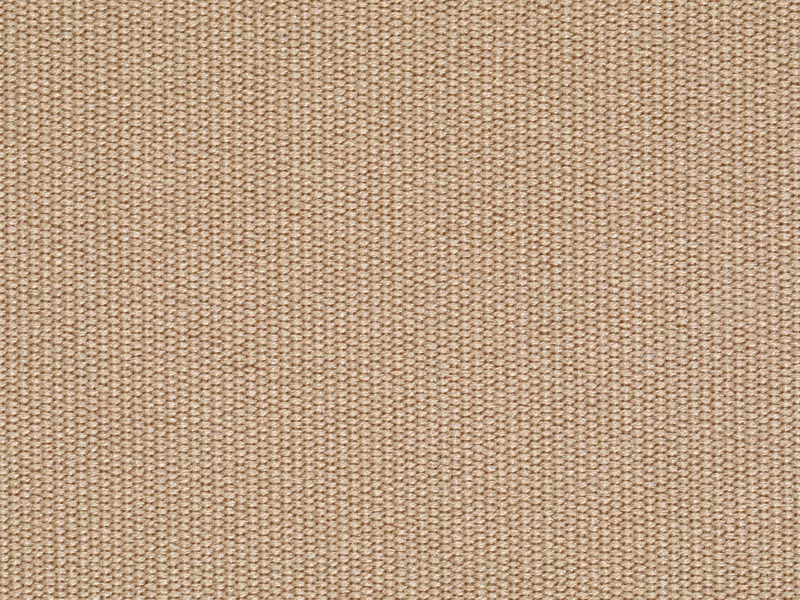

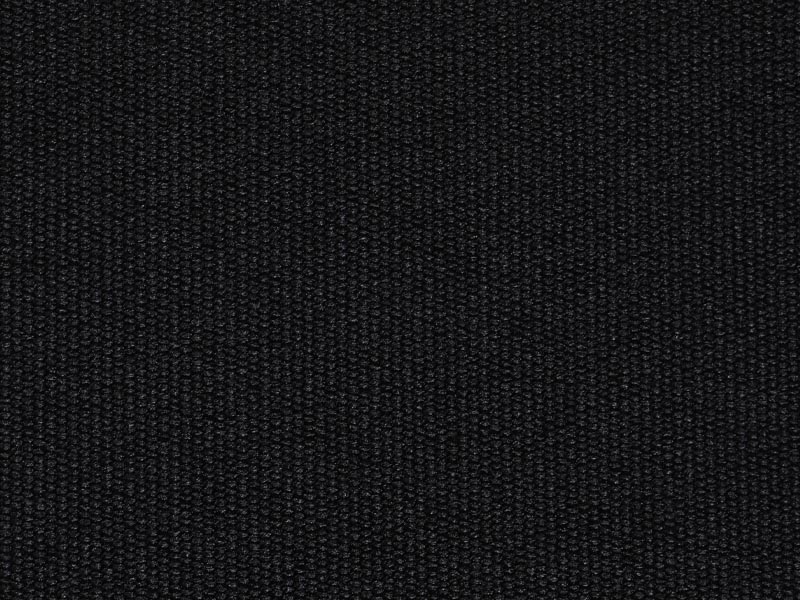

Tent Fabric is the backbone of any tent, providing shelter and protection from the elements. Traditionally, materials like polyester, nylon, and canvas have been used due to their strength and resistance to water and UV rays. However, with the growing concern for the environment, there is a shift towards materials that are not only durable but also sustainable. The quest for sustainable Tent Fabric is driven by the need to reduce waste, minimize the use of non-renewable resources, and create products that have a lower carbon footprint.

Manufacturers of Tent Fabric are increasingly turning to materials that are derived from renewable sources or are recyclable. One such material is polyester made from recycled plastic bottles. This not only reduces the amount of plastic waste that ends up in landfills but also decreases the demand for new petroleum-based materials. Recycled polyester is often used in the production of Tent Fabric because it retains the strength and water resistance of traditional polyester while offering a more sustainable alternative.

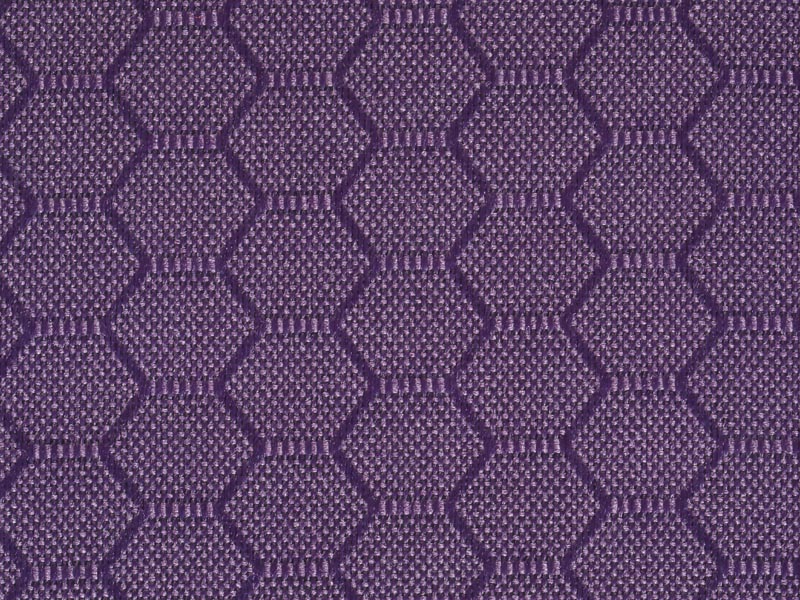

Another eco-friendly material gaining traction is Tencel, a lyocell fabric made from sustainably sourced wood pulp. Tencel is known for its softness, strength, and breathability, making it an choice for Tent Fabric. It is also fully biodegradable, which means it will break down naturally at the end of its life cycle, reducing its impact on the environment.

In addition to the materials used, the production processes for Tent Fabric are also being scrutinized for their environmental impact. Manufacturers are investing in energy-efficient machinery and implementing closed-loop systems to reduce water waste and chemical runoff. By using less water and fewer chemicals, the production of Tent Fabric becomes less taxing on the environment.

Some companies are also exploring the use of solar energy to power their factories, further reducing the carbon emissions associated with Tent Fabric production. This shift towards renewable energy sources is a significant step in the right direction, as it not only reduces the environmental impact of Tent Fabric manufacturing but also contributes to a more sustainable future for the industry.

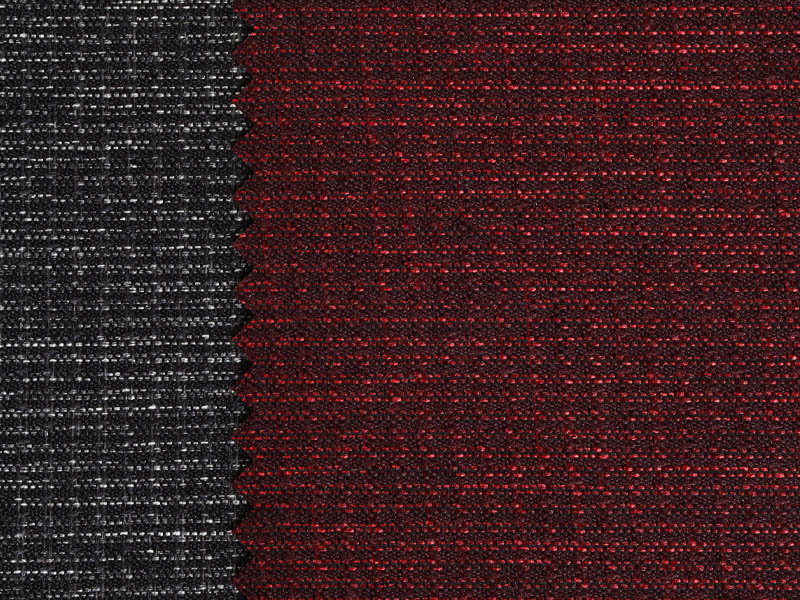

The development of recyclable Tent Fabric is a key area of focus for manufacturers looking to reduce waste. By creating Tent Fabric that can be easily recycled at the end of its life, manufacturers can help close the loop on material use, reducing the need for virgin materials and the associated environmental impacts.

Biodegradable Tent Fabric is another innovative solution that is being explored. These materials are designed to break down naturally over time, returning nutrients to the soil and leaving no trace. While the technology for fully biodegradable Tent Fabric is still in its infancy, the potential for such materials is immense, offering a truly sustainable option for outdoor enthusiasts.

Despite the progress made in developing eco-friendly Tent Fabric, there are challenges that manufacturers must overcome. The performance of sustainable materials must be on par with traditional materials, and the cost of production must be competitive. Research and development are crucial in this regard, as they drive innovation and improve the quality and affordability of sustainable Tent Fabric.

Manufacturers are also working to educate consumers about the benefits of sustainable Tent Fabric, as awareness is key to driving demand for these products. By choosing Tent Fabric made from recycled materials or those that are biodegradable, consumers can make a positive impact on the environment and support the growth of the sustainable outdoor gear market.

The future of Tent Fabric is one that is intertwined with the health of our planet. As manufacturers continue to adopt eco-friendly materials and production processes, the outdoor gear industry is taking significant steps towards sustainability. The development of recyclable and biodegradable Tent Fabric options is a testament to the industry's commitment to reducing its environmental impact. By choosing Tent Fabric that is both functional and sustainable, manufacturers, consumers, and the planet can all benefit. The journey towards a greener future is ongoing, and the Tent Fabric industry is playing a pivotal role in this transformation.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt