The Art and Science Behind Plain Weave Canvas

Posted by Admin

Wholesale High Quality plain weave canvas Manufacturers

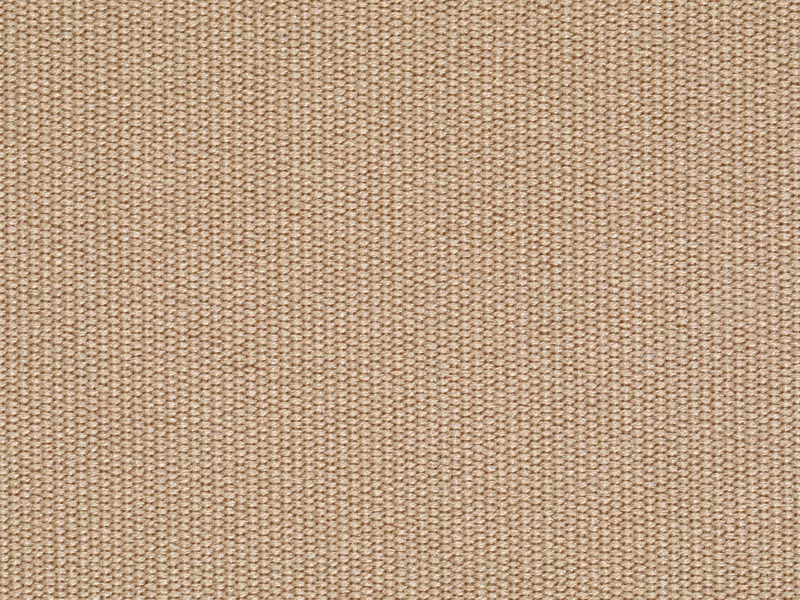

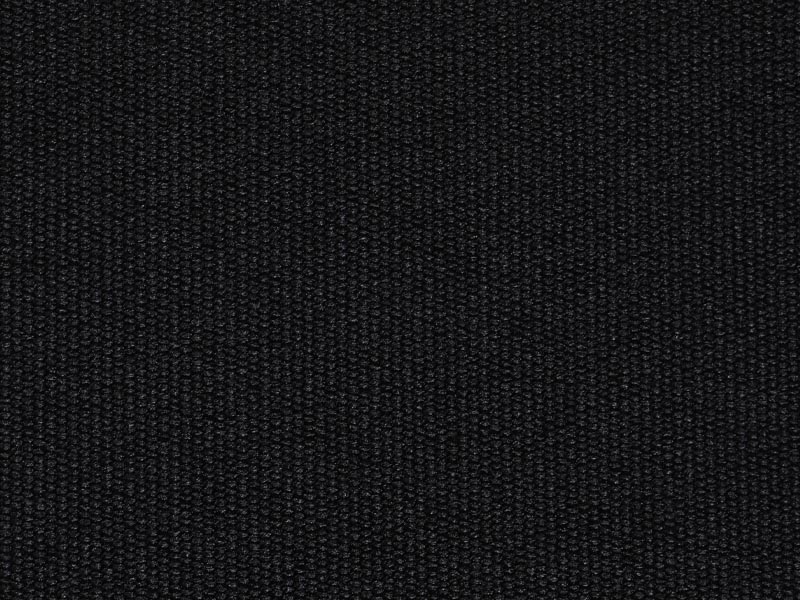

High Quality plain weave canvas, a widely used fabric known for its versatility and durability, is crafted using meticulous weaving techniques. In this article, we will delve into the art and science behind the production of High Quality plain weave canvas, exploring the interlocking of warp and weft threads, and the ingenious design and operation of weaving machines.

1. The Interplay of Threads:

High Quality plain weave canvas is created by interlacing the warp (longitudinal) and weft (horizontal) threads. This interlocking pattern results in a balanced, flat, and strong fabric. The warp threads are carefully stretched onto the loom and held under tension, forming a sturdy base, while the weft threads are passed over and under the warp threads in an alternating sequence, creating a tight yet flexible structure.

2. Loom Design and Innovation:

The weaving process of High Quality plain weave canvas primarily relies on looms specially designed for this purpose. Traditional manual looms, such as the handloom, were used in the past, requiring skillful craftsmanship and labor-intensive operations. However, with the advent of industrialization, mechanized and automated looms have revolutionized the production efficiency and quality control of High Quality plain weave canvas.

3. Mechanized Looms:

Mechanized looms, such as the power loom, brought about a significant transformation in the textile industry. With the power loom, the process of interlacing warp and weft threads is mechanized, significantly increasing the speed and precision of the weaving process. This innovation enabled mass production of High Quality plain weave canvas, making it accessible to a broader market.

4. Shuttle and Shuttleless Looms:

In the realm of mechanized looms, there are two main types: shuttle and shuttleless looms. Traditionally, shuttle looms were used, where a shuttle carrying the weft thread was manually passed between the warp threads. However, shuttleless looms, such as rapier looms, air-jet looms, and water-jet looms, came into existence, eliminating the need for a physical shuttle. These looms employ innovative mechanisms to propel the weft thread across the warp, allowing for faster and more efficient weaving.

5. Modern Technology and Automation:

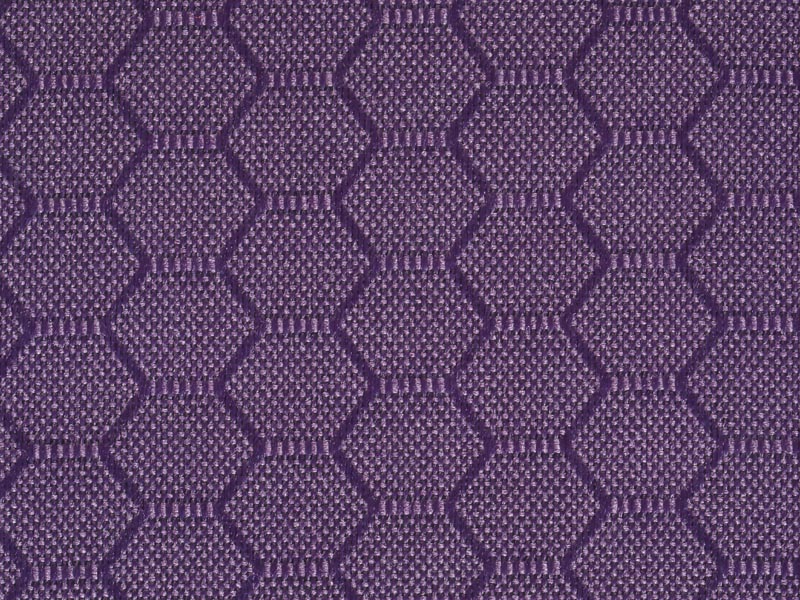

In recent years, with advancements in technology, computer-controlled looms, also known as electronic jacquard looms, have emerged. These sophisticated machines incorporate automation, allowing for precise control of the weaving process. With electronic jacquard looms, intricate patterns and designs can be woven into the High Quality plain weave canvas, providing endless creative possibilities.

7. Quality Control:

Ensuring the quality of High Quality plain weave canvas requires diligent monitoring and quality control measures. Advanced looms are equipped with sensors and cameras that constantly monitor various factors, such as thread tension, fabric width and thickness, and pattern accuracy. These monitoring systems aid in identifying any irregularities or defects during the weaving process, enabling swift corrective actions.

8. Future Prospects:

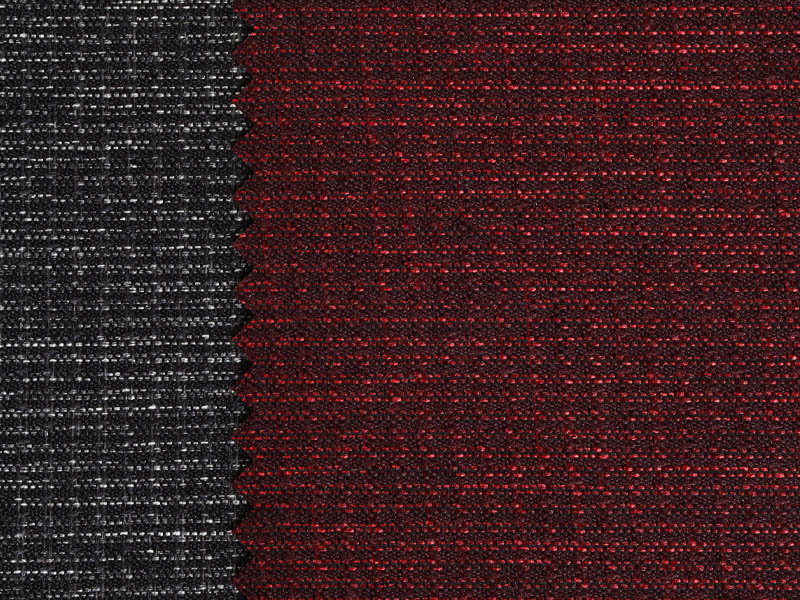

The production of High Quality plain weave canvases continues to evolve with technological advancements. Industry experts and researchers are striving to improve weaving efficiency, explore sustainable and eco-friendly materials, and enhance the versatility and aesthetics of High Quality plain weave canvas. Collaborations between textile manufacturers and designers are driving innovation, resulting in the creation of novel applications for this versatile fabric.

Conclusion:

High Quality plain weave canvas is a testament to the intricate artistry and scientific precision that goes into weaving a sturdy and visually appealing fabric. The interplay of warp and weft threads, coupled with the advancement of loom design and technology, has transformed the production of plain weave canvas. As we continue to push the boundaries of innovation, this versatile fabric opens up new possibilities in various industries, ensuring its continued relevance in the global marketplace.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt