Unveiling the Secrets of Luggage Fabric: A Fascinating Journey into the Manufacturing Industry

Posted by Admin

Direct Selling Professional luggage fabric Factory

In today's digital era, where travel has become a crucial part of our lives, luggage serves as an essential companion to our adventures. However, little do we realize the intricate details and expertise that go into the manufacturing of suitcase fabrics. In this article, we delve into the captivating world of Professional luggage fabric, exploring user interests, manufacturing techniques, and the profound effect it has on the travel experience.

User Interests in Professional luggage fabric:

The step towards understanding user interests in Professional luggage fabric lies in recognizing the key factors that directly affect their decision-making process. Travelers nowadays seek fabric materials that are both durable and lightweight, allowing for hassle-free mobility. Additionally, factors such as weather resistance, water repellency, and ease of cleaning are also key considerations. Luggage manufacturers strive to meet these demands by employing innovative techniques and utilizing the finest-quality fabrics.

Manufacturing Techniques for Professional luggage fabric:

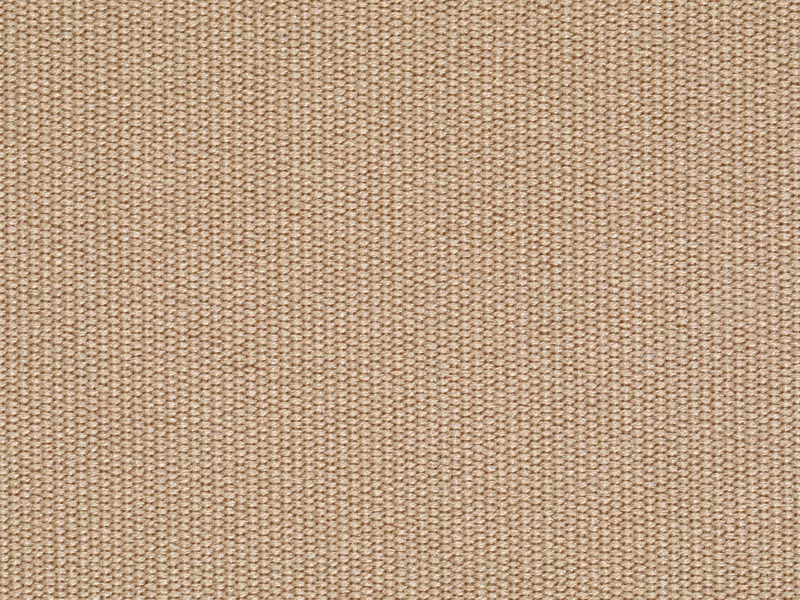

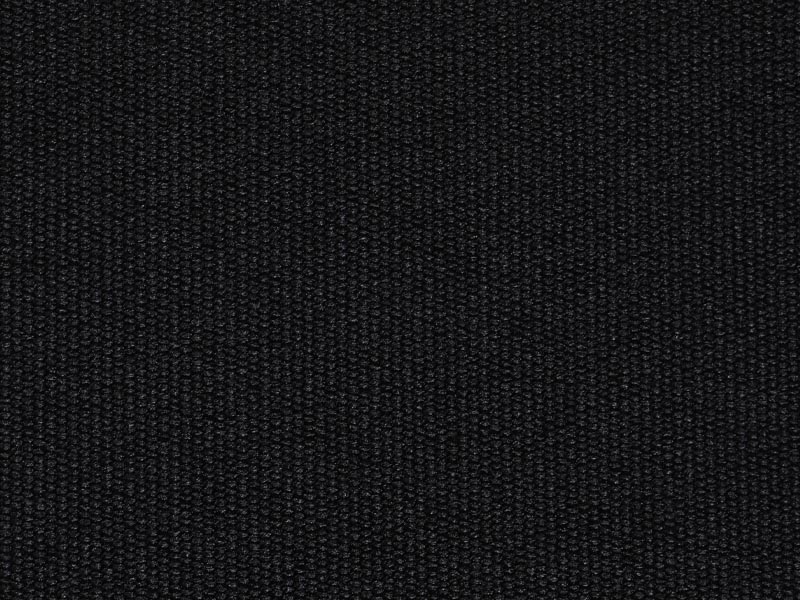

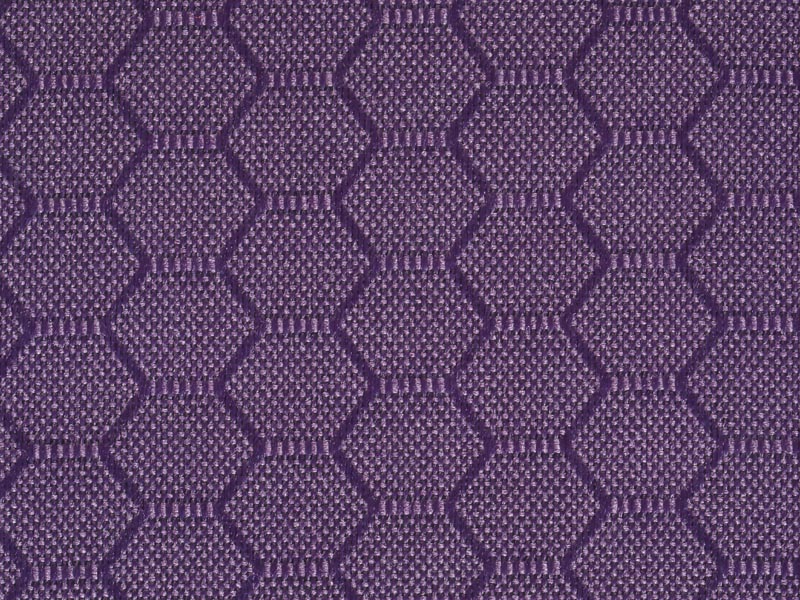

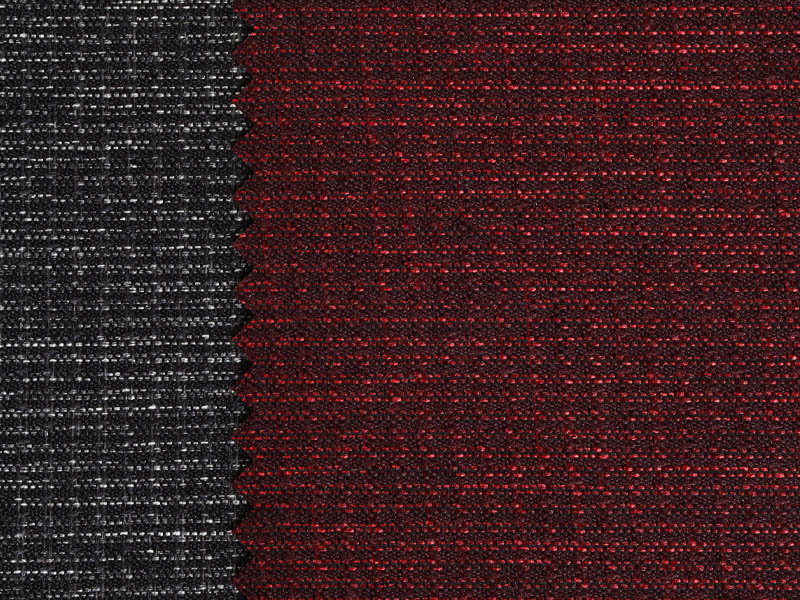

Professional luggage fabric manufacturing involves a meticulous process, ensuring the end product embodies reliability, aesthetics, and durability. High-quality materials like nylon, polyester, and polycarbonate blends are frequently used due to their robustness and resistance to tearing. The weaving process plays a vital role, often incorporating advanced techniques such as jacquard weaving or plain weaving to create unique patterns and designs, thereby enhancing the overall aesthetic appeal of the luggage. Specialized bonding methods further reinforce the fabric's durability, resulting in longevity and increased user satisfaction.

Impact on Travel Experience:

The fabric used in luggage has a significant impact on the overall travel experience. Travelers desire luggage that can withstand rough handling, endure different weather conditions, and provide effective protection for their belongings. Using advanced materials, such as ballistic nylon, guarantees high resistance to abrasion and tearing, granting users peace of mind while traveling. Moreover, lightweight fabrics contribute to reducing luggage weight, enabling users to pack more efficiently and avoid excess baggage fees.

Innovations in Luggage Fabric ManufacturingIn recent years, Professional luggage fabric manufacturers have embraced innovative technologies to cater to evolving user needs. The introduction of RFID-blocking fabrics has become essential for protecting personal information from potential electronic theft. Anti-scratch and stain-resistant coatings have also gained traction, ensuring the luggage maintains a pristine appearance even after frequent use. Furthermore, sustainable fabric production techniques have gained prominence, with-friendly materials such as recycled polyester being used to reduce environmental impact.

Future Prospects for Professional luggage fabric:

As the travel industry continues to evolve, so too does the outlook for Professional luggage fabrics. Researchers are exploring the integration of smart fabrics that possess interactive capabilities, such as built-in charging ports or temperature control features. Additionally, the incorporation of antimicrobial properties into luggage fabrics promises to enhance hygiene and minimize the risk of bacterial growth. Such advancements highlight the industry's commitment to continuously adapt and improve the travel experience.

Conclusion:

Professional luggage fabric manufacturing is an awe-inspiring realm that shapes the travel experience in profound ways. By catering to user interests, employing sophisticated manufacturing techniques, and embracing innovative technologies, Professional luggage fabric manufacturers strive to deliver products that exceed user expectations. What may appear as a simple fabric component holds immense potential for enhancing durability, aesthetics, and usability. As technology advances and user needs evolve, one can only anticipate further astonishing developments in the luggage fabric manufacturing industry.

English

English Français

Français Español

Español عربى

عربى Tiếng Việt

Tiếng Việt